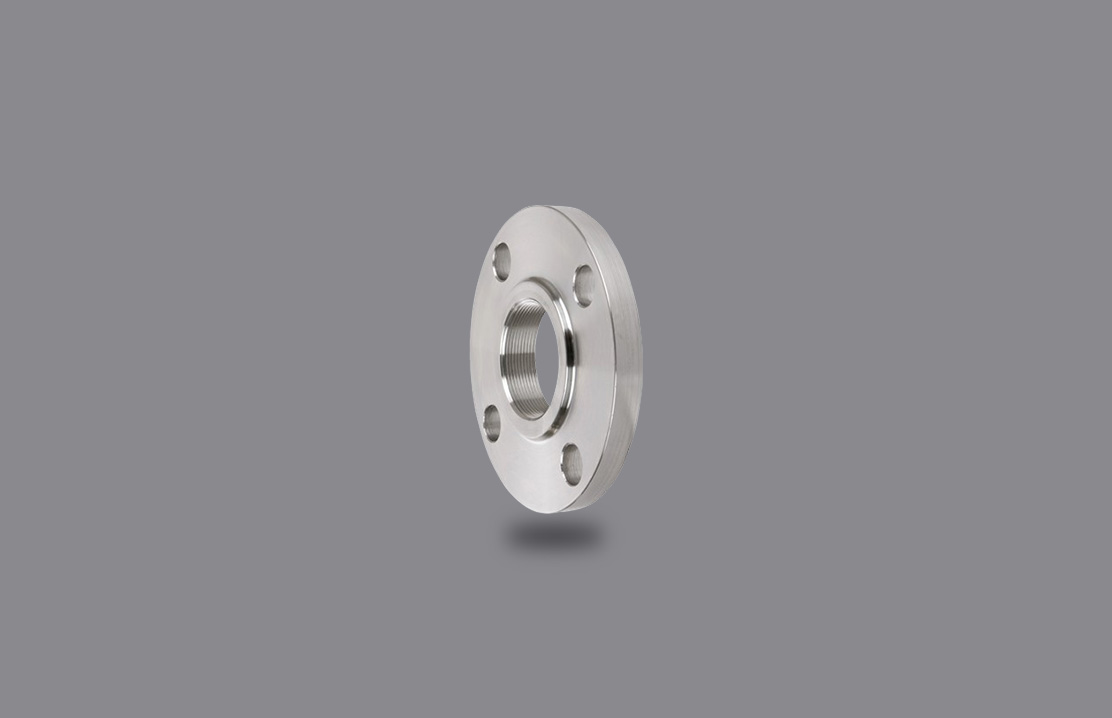

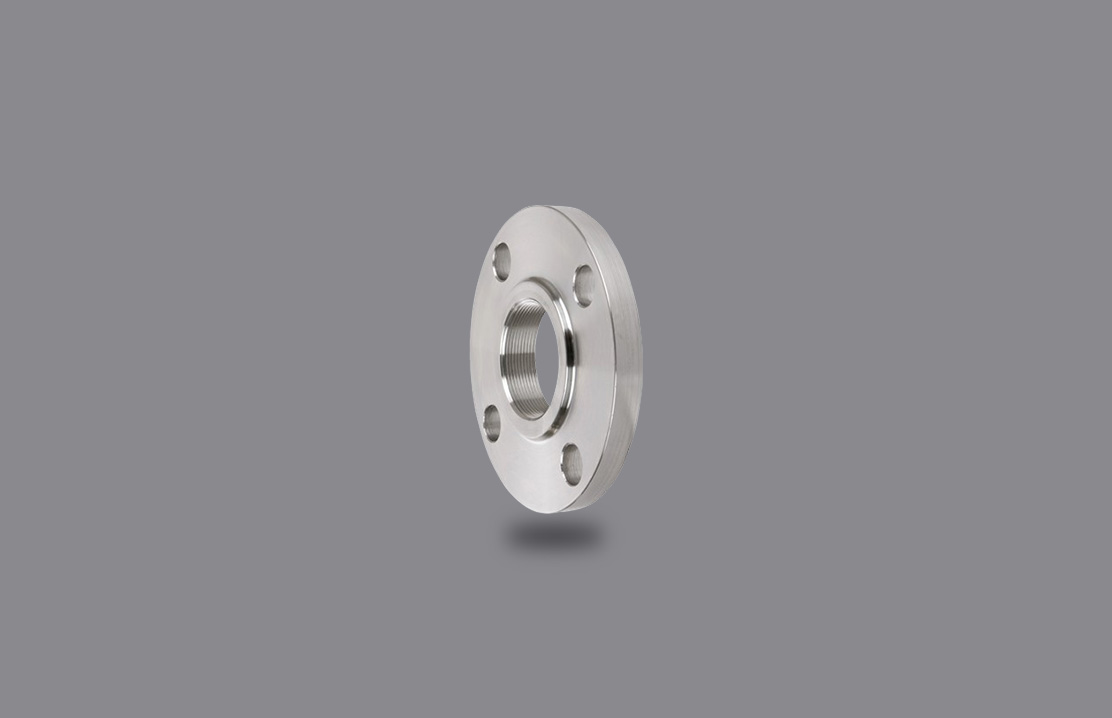

Alloy Steel Threaded Flange

Home - Alloy Steel - Alloy Steel Flanges - Alloy Steel Threaded Flange

Alloy Steel Threaded Flange

EBY Fasteners provides a convenient and adaptable solution for your piping systems with our selection of alloy steel threaded flange. Designed for applications where ease of assembly and disassembly are crucial, this flange features internal threads that mate with compatible threaded pipe. Their alloy steel construction offers strength, temperature resistance, and varying levels of corrosion resistance, ensuring a robust and enduring sealing solution

Manufactured in accordance with industry standards such as ASME and ASTM, EBY Fasteners’ alloy steel threaded flange guarantees precise dimensions, reliable pressure ratings, and compatibility with standard threaded piping components. Our meticulous quality control ensures that each flange meets rigorous tolerances and performance expectations

Whether you’re working with moderate-pressure pipelines in oil and gas, process piping in chemical plants, or auxiliary lines in power generation facilities, EBY Fasteners’ alloy steel threaded flange offers a practical and reliable choice. Select the appropriate alloy grade for your specific temperature, pressure, and chemical compatibility requirements

Whether you’re working with moderate-pressure pipelines in oil and gas, process piping in chemical plants, or auxiliary lines in power generation facilities, EBY Fasteners’ alloy steel threaded flange offers a practical and reliable choice. Select the appropriate alloy grade for your specific temperature, pressure, and chemical compatibility requirements

- F3 and F3A : These grades share similarities with F1 and F1A in terms of basic mechanical properties. However, they might be chosen for applications where improved machinability or weldability is crucial compared to the standard F1/F1A offerings. This can be beneficial during fabrication or installation processes.

- F7 : F7 strikes a balance between strength and toughness, making it suitable for moderate pressure and temperature service. An additional benefit is its enhanced corrosion resistance compared to some other grades. This can be advantageous in applications like chemical processing or certain oil and gas operations where the piping system might be exposed to corrosive fluids.

- F12 and F12L : These grades prioritize exceptional toughness at low temperatures while maintaining adequate strength. Compared to F11, they offer a wider range of suitability for extremely cold environments. They might be specified for cryogenic applications or piping systems operating in frigid conditions.

- F21 : This grade provides a good balance of strength and properties suited for moderate to high-temperature applications. It can be considered as an alternative to F5 for situations requiring good creep resistance at moderate to high temperatures, where the exceptional properties of F5 might not be entirely necessary.

- F91 : For applications demanding exceptional performance at extremely high temperatures, F91 steps up to the challenge. It boasts superior high-temperature strength and creep resistance compared to even F9. This makes it the go-to choice for critical high-temperature service in power plants or refineries where extreme temperatures and pressures are encountered

- Standards : ASTM A182/ASME SA182 for the material properties (chemical composition, mechanical strength, manufacturing) and ASME B16.5/B16.11/MSS SP-83 for the dimensional aspects (flange diameter, thickness, socket details, bolt holes). Choosing the right standards ensures a perfect fit between the flange and the pipe, along with compatibility with other piping components.

- Size : 1/2" (15 NB) to 4" (100 NB): This defines the nominal pipe size (NB) that the flange is designed to accommodate. The nominal pipe size refers to a designation system indicating the pipe's diameter. In this case, the flange ranges from a half-inch nominal diameter (15 NB) up to four inches nominal diameter (100 NB).

- Pressure Rating : Class 150, Class 300, Class 600, Class 900, Class 1500: This specification indicates the maximum pressure the flange can safely handle under operating conditions. The pressure classes range from Class 150 (suitable for lower pressures) to Class 1500 (designed for higher pressure applications). Selecting the appropriate pressure class is crucial for system safety.

- Thread Type : NPT (National Pipe Taper): This refers to the specific type of threads used on the inner diameter of the flange to connect with the pipe. NPT threads are a tapered thread design commonly used in piping systems. They create a tight seal when screwed together with a male NPT thread on the pipe end

- Ease of Installation and Disassembly : The threaded connection simplifies installation and removal compared to welded flange. This is especially beneficial for maintenance, modifications, or where temporary piping is needed.

- Versatility : Alloy steels offer a range of properties. You can choose from low-alloy grades for strength and moderate temperature service, stainless grades for corrosion resistance, or high-alloy grades for extreme conditions. This caters to various applications.

- Good for Moderate Pressures : Threaded flange is well-suited for many common industrial pressures, especially in smaller pipe sizes. They offer a reliable sealing solution for various pipelines and process systems.

- Potential for Compactness : Depending on the specific design, threaded flange connections can sometimes have a smaller footprint than other flange types. This can be advantageous in space-constrained areas.

- Leak-Potential with Vibration : Threaded connections, if not installed correctly or using appropriate thread sealant, may be more susceptible to leaks under vibration. Careful installation and maintenance are crucial

- Oil and Gas : In oil and gas operations, threaded flange is commonly used in lower-pressure sections of pipelines, auxiliary lines, and less critical process piping. Alloy steel options offer strength and some resistance to potentially corrosive fluids that might be present.

- Textile Machinery : Compressed air lines, water supply systems, and delivery lines for less aggressive dyes or chemicals in textile production facilities can utilize alloy steel threaded flange. Material selection hinges on compatibility with the specific fluids being transported.

- Industrial Machinery : Hydraulic systems, cooling loops, and even process piping within various industrial machines often incorporate threaded flange. Alloy steel offers the benefit of strength and, depending on the fluids involved, some corrosion resistance. The ease of assembly and disassembly makes them advantageous for maintenance purposes.

- Pumps and Compressors : Alloy steel threaded flange plays a role in connecting piping to pumps and compressors. They might be found on instrumentation lines, lubrication systems, or smaller auxiliary lines where pressure allows for their use.

- Dairy and Food Processing : While stainless steel grades like 304 or 316 are preferred, threaded flange can find application on less critical lines in dairy and food processing facilities. Hygiene and corrosion resistance are top priorities, and the ease of disassembly aids in cleaning and maintenance.

- Sugar Mills : Smaller auxiliary connections in sugar mills, such as pressure gauge lines, drain lines, or instrumentation additions, might utilize alloy steel threaded flange. Their ability to handle the moderate temperatures and potentially acidic environments encountered in sugar processing proves beneficial

Chemical Composition

| Element | Composition |

|---|---|

| Carbon (C) | Upto 0.15% |

| Manganese (Mn) | Range (0.30 - 0.60%) |

| Phosphorus (P) | Upto 0.025% |

| Sulfur (S) | Upto 0.025% |

| Silicon (Si) | Range (0.50 - 1.00%) |

| Chromium (Cr) | Range (4.00 - 6.00%) |

| Molybdenum (Mo) | Range (0.45 - 0.65%) |