Carbon Steel Swage Nipples (CONC. & ECC.)

Home - Carbon Steel - Carbon Steel Seamless Buttweld Fittings - Carbon Steel Swage Nipples (CONC. & ECC.)

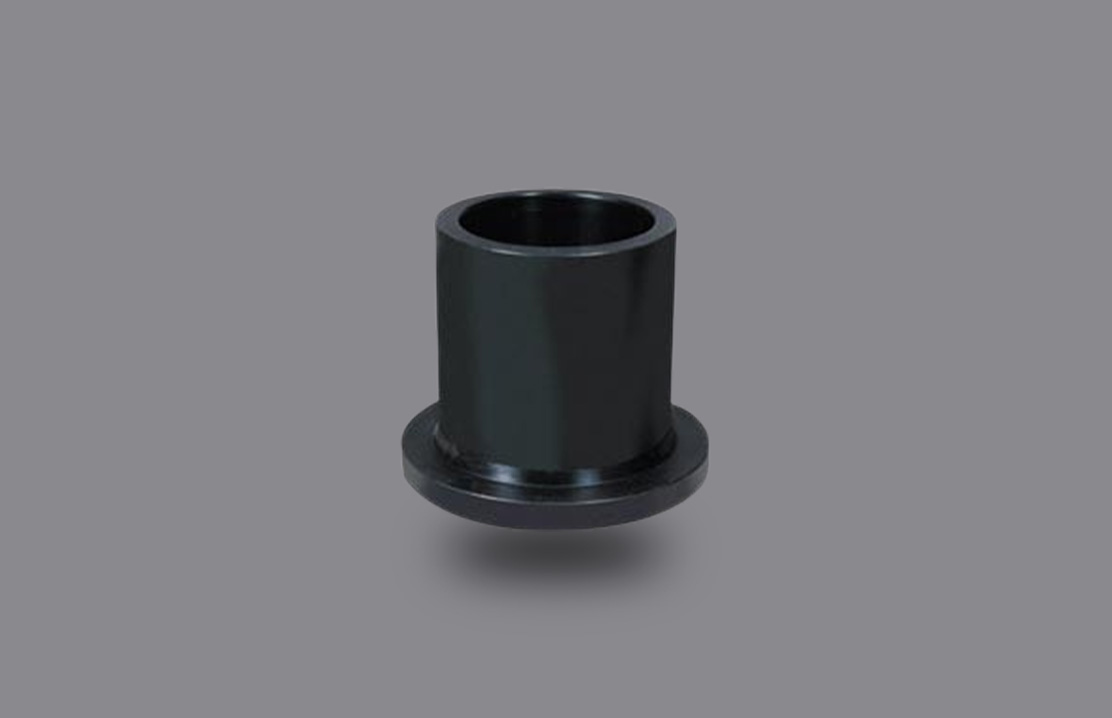

Carbon Steel Swage Nipples (CONC. & ECC.)

Enhance your industrial piping projects with EBY Fasteners’ Carbon Steel Swage Nipples. These concentric and eccentric nipples offer a seamless design for maximum strength and smooth diameter transitions. Their adaptability and range of sizes, pressure ratings, and connection options ensure the perfect fit for your system, optimizing flow and efficiency

Choose EBY Fasteners for quality-assured Carbon Steel Swage Nipples, meticulously manufactured to rigorous industry standards. Our team is here to provide expert guidance, ensuring you find the right nipple solution for your specific application

Simplify your piping installations, reduce downtime, and achieve reliable performance with EBY Fasteners’ Carbon Steel Swage Nipples (Concentric & Eccentric). Discover the difference of our commitment to quality, selection, and support. Contact us today and let our team help you streamline your piping projects

Simplify your piping installations, reduce downtime, and achieve reliable performance with EBY Fasteners’ Carbon Steel Swage Nipples (Concentric & Eccentric). Discover the difference of our commitment to quality, selection, and support. Contact us today and let our team help you streamline your piping projects

- ASTM Standards : In order to guarantee dependable performance and compliance with your piping system, carbon steel swage nipples must adhere to certain requirements for consistent quality, dimensions, and material qualities.

- ASTM A53 Grades A and B : These are very common pipe steels used for both welded and seamless construction. They offer a cost-effective option for general service applications where high pressures or extreme temperatures aren't primary concerns.

- ASTM A105 : This carbon steel grade is generally used for higher pressure and temperature applications compared to A53 or A106. Its forging process results in improved strength and toughness, making it suitable for more demanding piping systems.

- API 5L Grades B, X42, X46, etc. : API grades are designed specifically for line pipe in the oil and gas industry. They often have additional requirements for properties like toughness, impact resistance, and weldability, which are critical for pipelines transporting hydrocarbons.

- Grade Selection : The adaptability of the nipple for varying temperatures, its ability to withstand pressure, and its corrosion resistance are all influenced by the steel grade.

- WPL6, WPL3, etc. : These grades are intended for low-temperature situations.

- WPHY Grades : These are high-yield grades, with the number (42, 46, etc.) representing the minimum yield strength in ksi. Higher numbers signify greater strength

- Connection Type : Butt-Weld : This is the most popular way to attach swage nipples. Welding the nipple directly to the pipe creates a permanent, leak-tight seal that is suitable for high-pressure or critical applications.

- Size Range : The specified size ranges (1/2" to 10", 1/2" to 48") offer a large selection of nipple diameters appropriate for different types of pipe systems. For a good fit, the nipple's diameters must exactly match the diameters of the pipes you plan to join.

- Bending Radius : Whereas eccentric swage nipples offer an offset, concentrated swage nipples are straight. The bending radius of an eccentric nipple is frequently stated as a multiple of its diameter (1D, 2D, etc.). This radius establishes how sharp the curve is and how the nipple can be utilized to offset or create angles in your plumbing system. A kinder curve is produced with a bigger radius.

- Thickness of Fitting : The SCH10, SCH40, and other standards (schedules) specify the nipple's wall thickness. A wall that is thicker can withstand more pressure. To avoid leaks or breakdowns, you must choose a schedule that equals or exceeds the pressure requirements of your system.

- Importance of Specifications : It is essential to comprehend these criteria while choosing the right swage nipple for your plumbing system. Selecting the proper nipple with precise dimensions, an appropriate connection type, and wall thickness guarantees a safe, leak-proof connection and top performance in your plumbing system

- Smooth Diameter Transitions : Carbon steel swage nipples excel at facilitating seamless changes in pipe diameter. Their tapered design optimizes flow within your system, reducing turbulence and potential pressure losses.

- Concentric and Eccentric Options : Choose from concentric nipples for uniform flow and centered transitions, or eccentric nipples when you need to shift your pipe's centerline to navigate obstacles or accommodate specific design requirements.

- Durable Carbon Steel : These nipples are built from robust carbon steel, ensuring strength and resilience in industrial environments. Select the appropriate grade to match your system's chemical compatibility, temperature, and pressure demands.

- Versatile Sizing : Carbon steel swage nipples come in a wide range of sizes to integrate with various piping systems. Ensure a leak-free connection by precisely matching the nipple's dimensions to the pipes you'll be connecting.

- Pressure Handling Options : Select from different wall thicknesses (schedules) to find the ideal nipple for your system's pressure requirements. Choosing the right schedule is crucial for safety and preventing leaks.

- Standards Compliance : Swage nipples manufactured to ASME or MSS standards guarantee compatibility, predictability in sizing, and a secure fit within your piping network

- Refinery & Petrochemical : Carbon steel swage nipples are crucial components within the complex piping systems of refineries and petrochemical facilities. They facilitate the seamless connection of different-sized equipment, optimize flow characteristics by managing diameter changes, and enable the creation of smaller branch lines for targeted distribution.

- Chemical : The chemical processing industry relies on carbon steel swage nipples to ensure smooth integration of various pumps, valves, and other essential components within their process piping. These nipples effortlessly handle transitions in diameter and allow for the creation of specialized offshoots for sampling, process monitoring, or the controlled delivery of chemicals.

- Oil & Gas : Carbon steel swage nipples are widely used throughout the oil and gas sector. They are key elements in the construction of gathering pipelines, optimizing flow transitions, and facilitating equipment connections. Additionally, these nipples are found within processing facilities and play a role in creating distribution networks with varying pipe diameters.

- Power Plant : Within power plants, carbon steel swage nipples contribute to the reliable operation of water supply systems by connecting pipes of different sizes and integrating auxiliary equipment. They may also be utilized within less critical process systems where smooth transitions are needed for lower-pressure applications.

- Industrial Machineries : Carbon steel swage nipples are indispensable in the hydraulic, lubrication, and coolant systems of various industrial machines. They ensure compatibility between components of different sizes, optimize flow dynamics, and enable the creation of targeted branches within these systems for precise lubrication or focused cooling

Chemical Composition

| Element | Composition |

|---|---|

| Carbon | 2.1% max |

| Manganese | 1.65% max |

| Silicon | 0.6% max |

| Copper | 0.6% max |

| Sulfur | Traces |

| Phosphorus | Traces |

| Aluminium | Traces |