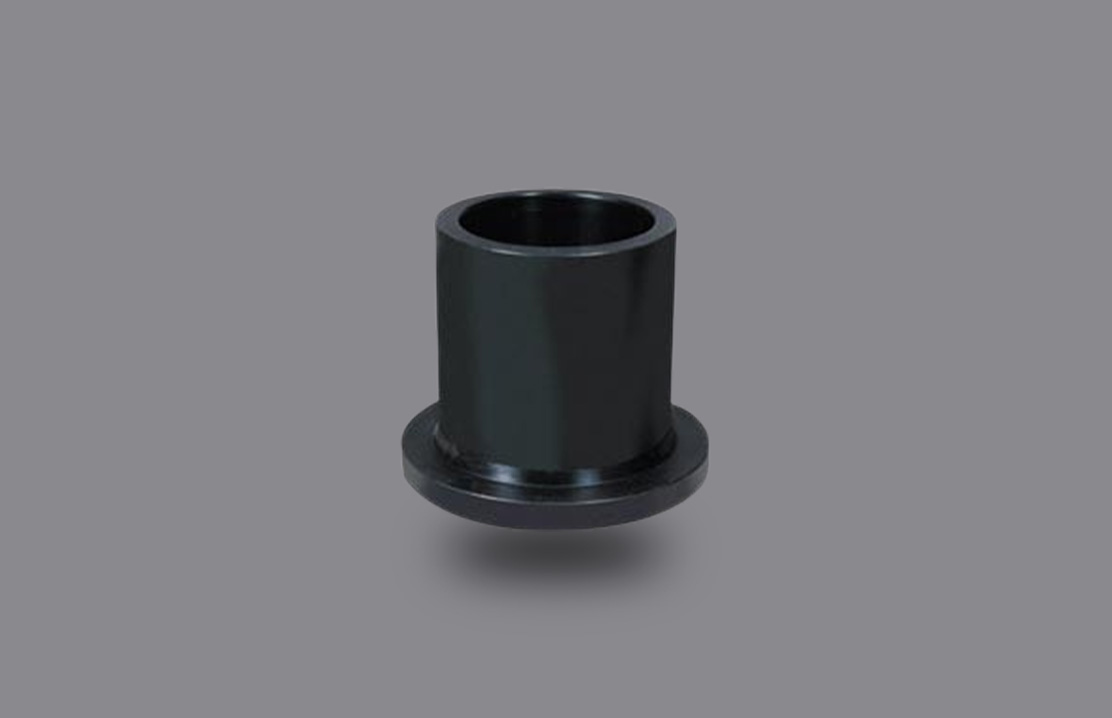

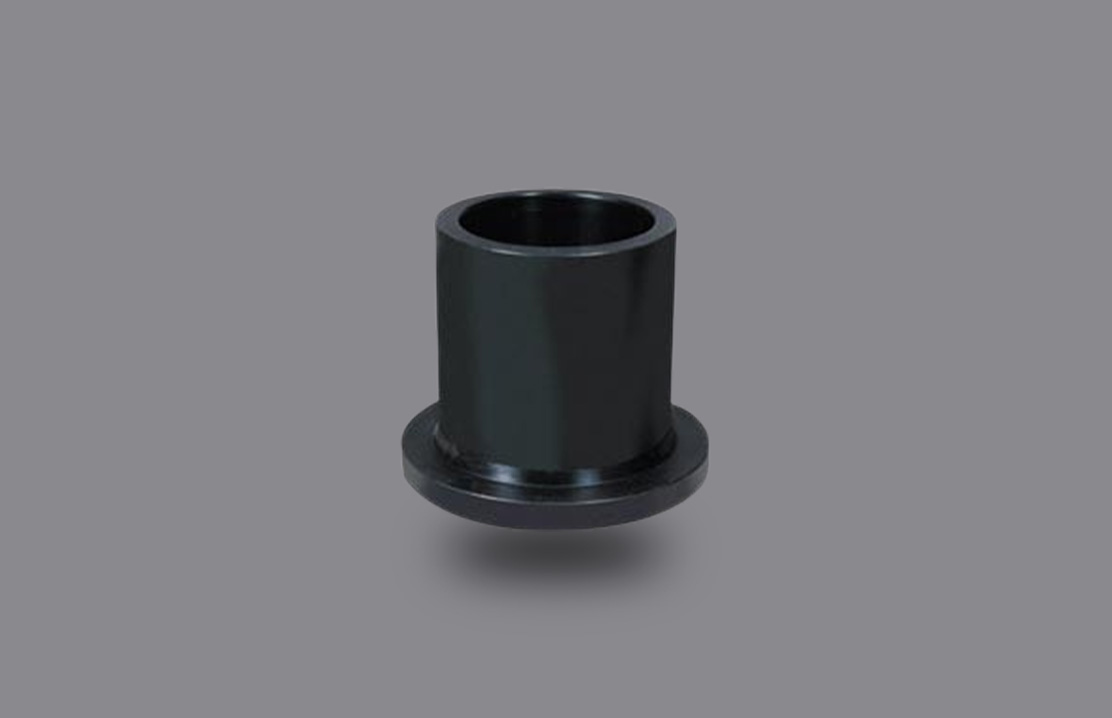

Carbon Steel Stubends

Home - Carbon Steel - Carbon Steel Seamless Buttweld Fittings - Carbon Steel Stubends

Carbon Steel Stubends

EBY Fasteners, a leading manufacturer, exporter, supplier, and stockist, offers premium Carbon Steel Stubends within their Carbon Steel Seamless Buttweld Fittings line. These robust fittings are meticulously crafted from high-grade materials, ensuring exceptional strength and durability. Adhering to rigorous industry standards (ASTM, ASME, BS, DIN, and others), EBY Fasteners’ Stubends are trusted by leading project management companies, engineering consultants, and EPCs

Experience the reliability of EBY Fasteners’ Stubends. Their seamless construction maximizes strength and leak resistance, ideal for demanding industrial applications. Choose from a wide range of sizes, pressure ratings, and material grades in carbon steel, low-temperature carbon steel, stainless steel, and specialty alloys. EBY Fasteners caters to diverse industries, including petrochemical, oil and gas, chemical processing, power generation, and more

Discover the EBY Fasteners advantage: quality products, exceptional value-added services, and a commitment to on-time delivery, regardless of order size. Let EBY Fasteners streamline your piping projects and ensure long-lasting performance

Discover the EBY Fasteners advantage: quality products, exceptional value-added services, and a commitment to on-time delivery, regardless of order size. Let EBY Fasteners streamline your piping projects and ensure long-lasting performance

- ASTM Standards : These standards provide the foundation for the quality, dimensions, and material properties that carbon steel stub ends must meet to ensure reliable performance and compatibility within your piping system.

- ASTM A234 WPA, WPB, WPC : This standard covers forged wrought carbon steel fittings (like stub ends) designed for pressure piping applications. Grades within this standard (WPA, WPB, WPC) represent variations in chemical composition and heat treatment, which slightly alter the steel's properties.

- ASTM A106 A, B, C : This standard focuses on seamless carbon steel pipes for high-temperature service. Stub ends are often made from sections of pipe, and adherence to this standard ensures consistency if your stub end is integrated with a piping system using A106.

- ASTM A420 WPL3 / A420 WPL6 / MSS-SP-75 WPHY 42/46/52/56/60/65/70 : These standards deal with low-temperature wrought carbon steel fittings. Stub ends made from these grades are specifically designed for applications where the piping system will operate in cold environments.

- Grade Selection : The grade of steel plays a significant role in determining the stub end's suitability for different temperatures, pressure handling capabilities, and resistance to corrosion.

- A, B, C (common across standards) : These letter grades generally denote increasing carbon content within the steel. This translates to slightly higher strength and hardness but potentially reduced ductility as you progress from A to C.

- WPL3, WPL6, etc. : These grades are designed for low-temperature environments.

- WPHY Grades : These are high-yield-strength grades, where the number (42, 46, etc.) denotes the minimum yield strength in ksi (thousands of pounds per square inch). Higher numbers indicate greater strength.

- Importance of Matching Grades : When choosing a carbon steel stub end, selecting a grade that aligns with the other components of your piping system and matches its specific operating conditions is crucial. This ensures consistency of material properties across the entire section of piping, minimizing potential leaks or failures due to mismatched strength or temperature tolerances

- Connection Type : Butt-Weld: This is the most common connection type for stub ends. It involves welding the stub end directly to the pipe, creating a permanent, leak-tight seal, ideal for high-pressure or critical applications.

- Size Range : The indicated size ranges (1/2" to 10", 1/2" to 48") provide options for stub ends suitable for a wide variety of pipe sizes. It's essential to match the stub end's diameter precisely to the diameter of the pipe you will be connecting for a proper fit.

- Bending Radius : The stub end's bending radius is often expressed as a multiple of its diameter (1D, 2D, etc.). This radius determines the curve's sharpness, impacting how the stub end can be used to create angles or offsets within your piping system. A larger radius provides a gentler curve and may be needed for specific design requirements.

- Thickness of Fitting : Standards like SCH10, SCH40, etc. (Schedules) dictate the wall thickness of the stub end. A thicker wall provides a greater pressure handling capability. It's essential to select a schedule that matches or exceeds the pressure requirements of your system to prevent leaks or failures.

- Importance of Specifications : Understanding these specifications is vital when selecting the appropriate stub end for your piping network. Choosing the right stub end with accurate measurements, a suitable connection type, bending radius, and wall thickness ensures a secure, leak-tight connection and optimal performance within your piping system

- Seamless Construction : Buttweld stub ends are manufactured using processes that result in a seamless design. This means there are no weak points from welding seams, enhancing their strength and making them ideal for higher-pressure systems.

- Lap-Joint Flange Connection : Stub ends are specifically designed to work in conjunction with lap-joint flanges. This provides a flexible and cost-effective piping solution, particularly in applications where alignment may be an issue or regular maintenance access is required.

- Robust Carbon Steel Construction : Manufactured from carbon steel, these stub ends offer strength, durability, and resilience in demanding industrial settings. Careful selection of the specific grade is important to ensure the stub end can handle your system's operating temperatures, pressures, and chemical compatibility.

- Size Range : Carbon steel stub ends are available in various diameters to accommodate diverse piping systems. Matching the stub end's diameter precisely to the pipes you're connecting is crucial for ensuring a secure and leak-free joint.

- Wall Thickness Options (Schedules) : Stub ends come in various wall thicknesses, allowing you to select the optimal schedule based on your system's pressure requirements. Choosing a schedule that aligns with your system's needs ensures safe and reliable operation.v

- Adherence to Standards : Carbon steel stub ends manufactured to standards like ASME or MSS ensure predictability in sizing, tolerances, and compatibility. These standards simplify installation and guarantee a secure fit within your piping network

- Refinery & Petrochemical : Within refineries and petrochemical plants, stub ends play a crucial role in enabling the use of lap-joint flanges throughout process lines. This provides flexibility, facilitating the integration of equipment, transitions in pipe diameter, and temporary termination of lines during maintenance or construction.

- Chemical : Stub ends streamline the construction of chemical piping networks, allowing for the integration of lap-joint flanges that connect pumps, valves, and other equipment. The adaptability provided by the lap-joint connections aids in maintenance and modifications of process lines. Stub ends also enable convenient creation of sampling taps or instrumentation integration points.

- Oil & Gas : Carbon steel stub ends are valuable components in the oil and gas industry. They enable the use of lap-joint flanges for pipeline segments, providing flexibility, and simplifying the process of making connections or repairs in the field. Stub ends and lap-joint flanges are also used for equipment connections and are found within smaller-diameter gathering lines.

- Power Plant : Stub ends find applications within power plant water supply systems where their adaptability makes them well-suited for less critical portions of the system. They may also be found in auxiliary systems where ease of maintenance or equipment connections are important factors within the piping design.

- Industrial Machineries : In the world of industrial machinery, stub ends and lap-joint flanges can be found in certain types of hydraulic systems, offering flexibility in component integration and ease of access for maintenance tasks. Adaptability in design is a key advantage when incorporating stub ends and lap-joint connections within complex machinery

Chemical Composition

| Element | Composition |

|---|---|

| Carbon | Up to 2.1% |

| Manganese | Up to 1.65% |

| Silicon | Up to 0.6% |

| Copper | Up to 0.6% |

| Sulfur | Present |

| Phosphorus | Present |

| Aluminium | Present |